#CRANE RIGGING FORMULAS FULL#

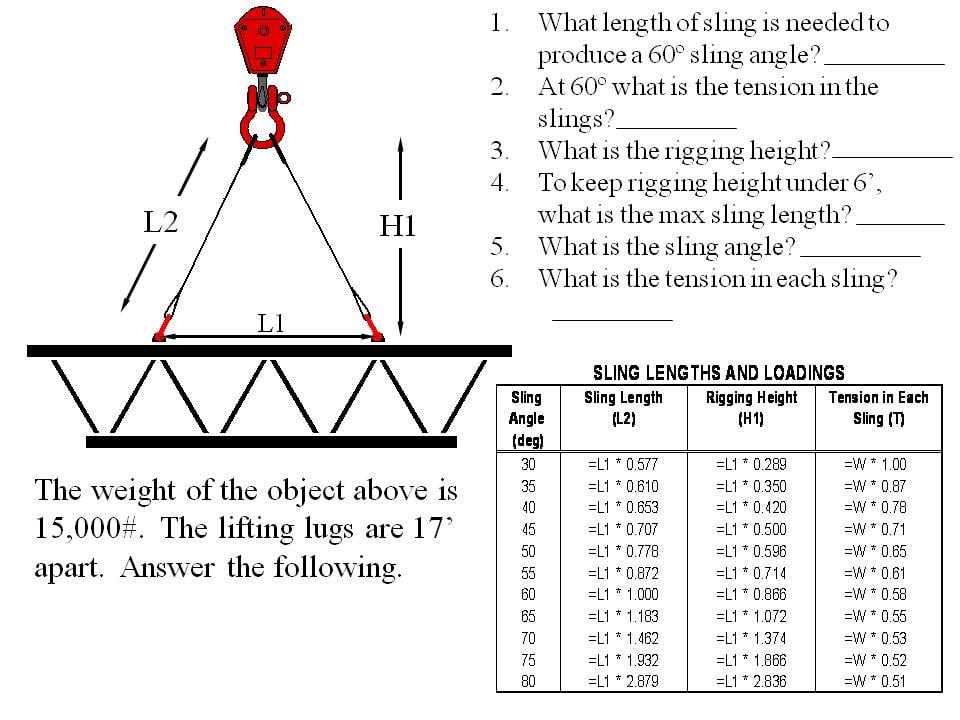

The load capacity assumes that the sling is in a vertical hitch.To account for the capacity of both legs of the sling, multiply the sling’s vertical load capacity by two.The sling in this example is rated for 2,800 pounds for a vertical hitch. This should be clearly indicated on the sling’s identification tag. Next, find the vertical load capacity of the sling.In this example, the load is 4,200 pounds.

Start by verifying the total weight of the load.The Reduced Work Load method looks directly at the angle to determine the reduced work load on the sling.There are a couple of different methods to determine how your working load limit is affected by the sling’s angle.This chapter will familiarize you with general safety practices, inspection requirements, proper identification of equipment limits, proper storage of equipment, and an introduction to the different hitches and slings you’ll use. The dangers of rigging work are greatly amplified for those who are unfamiliar with the basics of rigging safety.This course will provide an introduction to general rigging equipment and safety, an outline of various sling types and their capacities and characteristics, and an overview of steel erection rigging operations, including hand signals for crane operations. The safety of a rigging project depends on the proper preparation of the necessary components at each stage of the lift, from the sling, its attachments, and the lifting device, to the riggers, crane operators, and other personnel involved.Take a peek! Preview the following excerpt: Rigging-Engineering-Calculations-Sample-Preview-Watermarked. For those who really need to get into depth, references are made to useful standards and other resources. Those who simply need a look-up reference for a formula can use the book in that way. In (relatively) simple language, principles are explained, formulae are derived and applied with worked examples in both US customary and metric units. Determine crushing forces in a wrapped basket hitch.Calculate suspension forces in complex arrangements.Calculate lashing forces in a transport arrangement.Calculate sag and tension in a suspended line.This volume is a “how-to” resource for many of the calculations required in rigging operations and is intended to complement “ Rigging Engineering Basics” or can be used stand-alone.

0 kommentar(er)

0 kommentar(er)